$1,590.00 Original price was: $1,590.00.$999.00Current price is: $999.00.

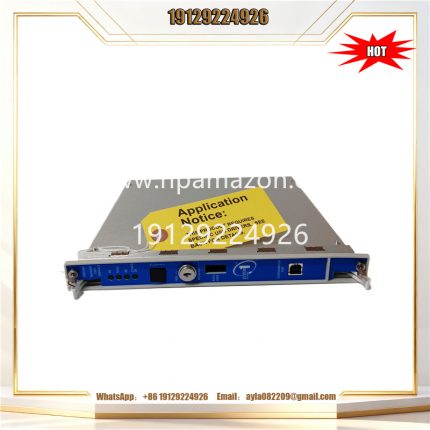

The Bently Nevada 3500/33 149986-01 is a 16 – channel relay module in the 3500 system, offering 16 relay outputs that can be programmed based on alarm conditions of other monitor modules in the rack for flexible and reliable control in industrial machinery monitoring setups.

| Parameter | Details |

|---|---|

| Model | 3500/33 (Product Name) / 149986-01 (Material Number) |

| Manufacturer | Bently Nevada |

| Product Type | 16 – Channel Relay Module |

| Relay Outputs | 16 |

| Relay Type | Single – Pole Double – Throw (SPDT) |

| Relay Environmental Sealing | Epoxy – sealed |

| Relay Arc Suppressor | 250 vrms installed as standard |

| Relay Contact Life | 10,000 cycles |

| Alarm Drive Logic | Programmable using AND and OR logic; can use alarming inputs (alert and danger statuses), not – ok individual measured variables from any monitor channel or combinations in the rack |

| Power Consumption | 5.8 watts (typical) |

| Dimensions (Height x Width x Depth) | 241 mm x 24.4 mm x 242 mm (9.50 in x 0.96 in x 9.52 in) |

| Weight | 0.7 kg (1.6 lb) |

| DC Specifications (Resistive Load) | – Min Switched Current: 100 ma @ 5 vdc

– Max Switched Current: 3 a – Max Switched Power: 70 w @ 24 vdc, 10 w @ 48 vdc, 9 w @ 60 vdc – Max Switched Voltage: 125 vdc |

| AC Specifications (Resistive Load) | – Max Switched Current: 3 a

– Max Switched Power: 1200 va – Max Switched Voltage: 250 vac |

| Installation | Can be placed in any slot to the right of the transient data interface (TDI) module in the 3500 rack |

| LED Indicators | – OK LED: Illuminated when the module is operating properly

– Ch Alarm LED: Illuminated when relay channel is in an alarm state |

The BENTLY 3500 system is a professional machinery protection and condition monitoring solution widely used in industries like oil and gas, power generation, and petrochemicals. It adopts a modular design, allowing flexible configuration of monitoring modules (e.g., vibration, temperature, and speed modules) to track key operating parameters of rotating equipment such as turbines and compressors. By collecting and analyzing data in real time, it can promptly identify issues like equipment imbalance or bearing wear, trigger alarms or shutdowns when thresholds are exceeded, and effectively prevent unexpected equipment failures to ensure production continuity.

No account yet?

Create an Account

Reviews

There are no reviews yet.