$5,500.00 Original price was: $5,500.00.$2,899.00Current price is: $2,899.00.

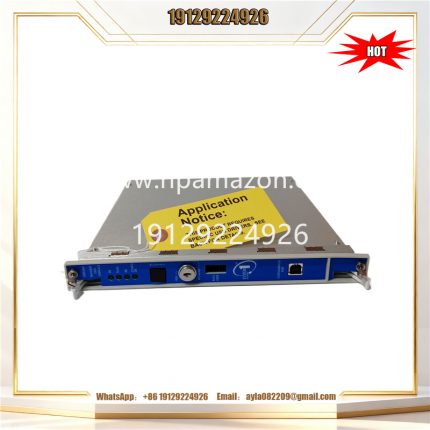

BENTLY NEVADA 3500/65 145988-02 is a high – performance 16 – channel temperature monitor module, designed for seamless integration into the 3500 machinery protection system. It can accurately measure temperature inputs from various sensors like RTDs and thermocouples, offering real – time thermal condition monitoring for industrial applications.

| Parameter | Value |

|---|---|

| Model Number | 3500/65 145988 – 02 |

| Product Type | 16 – Channel Temperature Monitor Module |

| Manufacturer | BENTLY NEVADA |

| Input Types | Accepts Resistance Temperature Detector (RTD) and Isolated Tip Thermocouple (TC) temperature inputs |

| Number of Channels | 16 |

| Input Impedance | Greater than 1 MΩ for each lead input |

| Power Consumption | 3 watts (nominal) |

| Operating Temperature Range | – 30 °C to + 65 °C (- 22 °F to + 150 °F) |

| Storage Temperature Range | – 40 °C to + 85 °C (- 40 °F to + 185 °F) |

| Dimensions (Length × Width × Height) | 241.3 mm × 24.4 mm × 241.8 mm (9.50 in × 0.96 in × 9.52 in) |

| Weight | 0.91 kg (2.0 lbs) |

| LED Indicators | – OK LED: Indicates when the module is operating properly – TX/RX LED: Indicates communication with other modules in the 3500 rack – Bypass LED: Indicates when the monitor is in bypass mode |

| Alarm Setpoints | User – programmable |

| Signal Conditioning | Conditions input signals |

| Compatibility | Compatible with 3500 rack configuration software |

| Humidity Range | 5% – 95%, non – condensing |

| Accuracy | ± 0.1% of full scale (as per some references for similar modules in the series, may need verification) |

| Resolution | 0.01 °C (0.02 °F) (as per some references for similar modules in the series, may need verification) |

The BENTLY 3500 system is a professional machinery protection and condition monitoring solution widely used in industries like oil and gas, power generation, and petrochemicals. It adopts a modular design, allowing flexible configuration of monitoring modules (e.g., vibration, temperature, and speed modules) to track key operating parameters of rotating equipment such as turbines and compressors. By collecting and analyzing data in real time, it can promptly identify issues like equipment imbalance or bearing wear, trigger alarms or shutdowns when thresholds are exceeded, and effectively prevent unexpected equipment failures to ensure production continuity.

No account yet?

Create an Account

Reviews

There are no reviews yet.